Grain Rice and Flour Mill Construction in Lahore

Lahore isn’t just a city of history and culture it’s also one of Pakistan’s biggest hubs for food production. With more people moving in every year, the demand for rice and flour keeps rising. Families need affordable food, bakeries need a steady supply, and exporters look to Lahore as a key point for processing grain.

That’s why grain rice and flour mill construction in Lahore has become so important. New mills aren’t just buildings, they’re part of the food chain that keeps the city running. They help with food security, create jobs, and support farmers from nearby areas.

In simple words, building a rice or flour mill here isn’t only about business. It’s about making sure the city has enough food today and for the future as Lahore keeps growing.

Why Invest in Rice and Flour Mill Construction in Lahore?

If you’re thinking about starting a food-related business, rice mill construction in Lahore is one of the smartest moves you can make. The city has the right mix of demand, supply, and future growth that makes mill projects successful. Let’s break it down.

1. Local Demand and Food Security

Lahore is home to millions of people, and the number keeps growing every year. Everyone needs basic food like flour and rice daily. Local mills make sure families get fresh, affordable products without depending too much on outside suppliers. When more mills are built, the city becomes stronger in food security and less affected by market shortages.

Also Read Best Construction Company in Lahore

2. Strategic Location of Lahore for Punjab Grain Supply

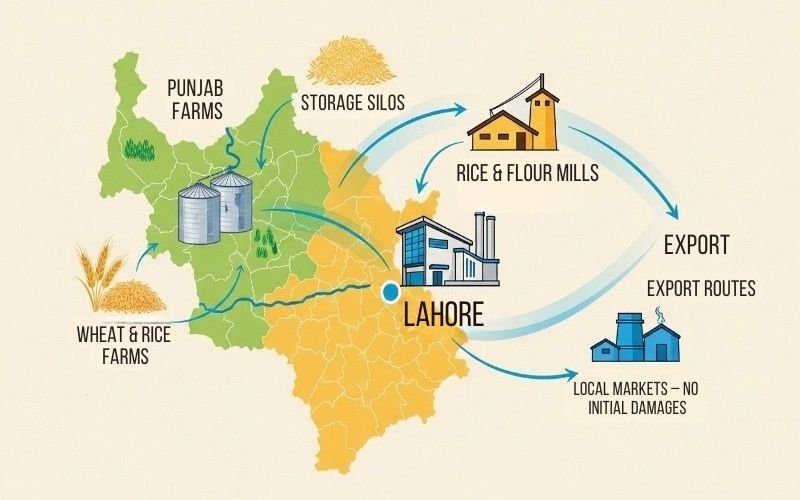

Lahore sits at the heart of Punjab, Pakistan’s top agricultural region. Wheat and rice from surrounding districts like Sheikhupura, Kasur, and Gujranwala are easy to bring into the city. This makes Lahore a natural center for processing grain because transport is cheaper and faster.

3. Export Potential for Rice & Flour

Pakistan’s rice is famous worldwide, especially Basmati. Lahore’s mills are close to exporters and shipping hubs, which helps meet global demand. By building modern rice and flour mills, businesses in Lahore can not only serve the local market but also take part in international trade.

Learn More About Our Turnkey Construction Services

Step-by-Step Process of Building a Mill

Starting a mill project can feel big, but when you break it down, the flour mill construction process in Pakistan is easier to understand. In Lahore, contractors usually follow these main steps:

1. Site Selection & Soil Testing

The first step is choosing the right land. Soil tests are done to make sure the ground can hold heavy machinery and large buildings. Picking a location near main roads in Lahore also helps reduce transport costs.

2. Civil Works & Structure Development

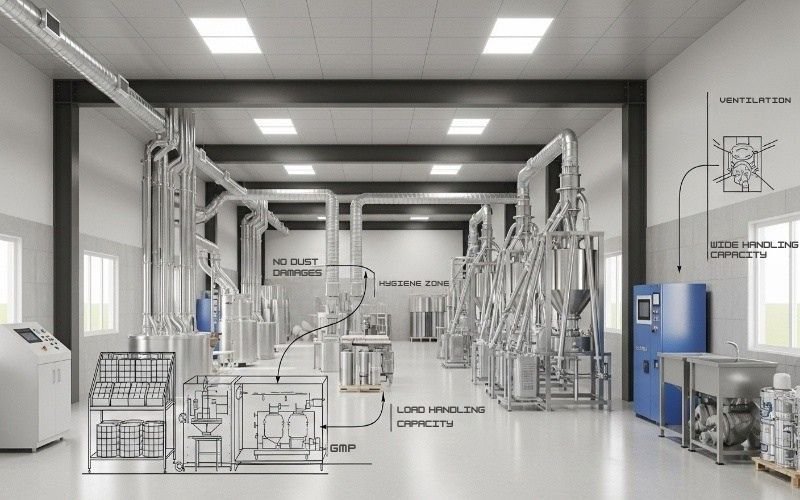

Once the land is ready, the foundation and main building are built. This includes strong walls, floors that can carry heavy loads, and storage areas for grain. Good ventilation and dust control are also added at this stage.

3. Machinery Installation (grinders, silos, sifters)

After the structure is complete, machines are installed. These include grinders to crush wheat, sifters to clean rice, and silos to store grain safely. Choosing modern equipment makes the mill faster and more reliable.

4. Electrical, Automation & Commissioning

Finally, power systems, wiring, and automation controls are set up. Once everything is tested, the mill is ready to start production.

Mill Construction Timeline Example

| Mill Size | Average Timeline |

|---|---|

| Small | 6–8 months |

| Medium | 8–10 months |

| Large | 12–14 months |

Project highlight: a mid-sized mill in Raiwind, Lahore completed in under 10 months after following this step-by-step process.

Cost Breakdown of Rice and Flour Mill Projects

If you’re planning to set up a mill, one of the first questions is always about money. The cost to build a flour mill in Lahore depends on land, construction, machines, and utilities. Let’s break it down in simple terms so you can see where the investment goes.

1. Land Cost (Urban vs Outskirts)

Land inside Lahore city is more expensive but gives easy market access. On the outskirts, land is cheaper and offers more space, which is ideal for larger mills.

2. Civil & Structural Works (Cement, Steel, Labor)

Strong structures are the backbone of any mill. Costs here cover cement, steel, and skilled labor. Prices can change with market rates of construction materials.

Check today’s Saria Price in Pakistan for better cost planning.

3. Machinery (Imported vs Local Suppliers)

Flour mills need grinders, silos, and sifters. Local machinery is affordable, but imported machines often last longer and give higher output.

4. Utilities & Setup (Electricity, Gas, Water)

Reliable electricity, gas, and water supply are must-haves. These setups add to the initial cost but ensure smooth daily operations.

| Estimated Cost Ranges | Small Mill | Medium Mill | Large Mill |

|---|---|---|---|

| Land + Construction | PKR 40M–60M | PKR 80M–120M | PKR 200M+ |

| Machinery & Setup | PKR 30M–50M | PKR 70M–100M | PKR 150M+ |

| Utilities & Other Costs | PKR 10M–20M | PKR 30M–50M | PKR 80M+ |

| Total Estimate | PKR 80M–130M | PKR 180M–270M | PKR 430M+ |

Design & Compliance Considerations

When you’re planning grain mill design in Lahore, it’s not just about walls and machines. A mill must follow food safety, legal, and worker protection rules. These steps ensure smooth operations and long-term success.

1. Food Safety & Hygiene Standards (GMP, ventilation, dust control)

Grain and flour must stay clean and safe. Good ventilation and dust control systems reduce health risks. Following GMP (Good Manufacturing Practices) keeps the product fresh and market-ready.

External Reference: Food and Agriculture Organization (FAO) – Learn more about Pakistan food safety and grain storage standards.

2. Government Approvals & Legal Permits

Before construction starts, you’ll need permits from local authorities. These cover land use, building safety, and environmental checks. Getting approvals early saves you delays later.

3. Worker Safety & Structural Load Handling

Mills run heavy machines and carry large grain loads. The design should handle strong vibrations, heavy weight, and fire safety. Clear emergency exits and worker training are also a must.

Case Study: A flour mill in Lahore passed all inspections by focusing on dust control and strict worker safety measures. This simple focus helped them run without shutdowns or penalties.

Choosing the Right Construction Partner in Lahore

Building a mill is a big investment, so picking the right team matters. The right flour mill construction company in Lahore can save you time, money, and stress. On the other hand, a wrong choice may lead to delays and costly mistakes.

1. Key Things to Check (Past Projects, Local Expertise, Full-Service Ability)

1. Look at past mill projects to see real results.

2. Check if the company knows local soil, climate, and rules.

3. Full-service firms handle design, civil works, and permits all under one roof.

For example, Highland Properties and Construction, known as one of the best construction companies in Lahore, provides complete mill project support from planning to handover.

2. Warning Signs (Hidden Costs, no Mill Experience, Unclear Timelines)

Some contractors may show low prices at the start but later add hidden costs. Others may have no direct experience with mills, which leads to design errors. Unclear timelines are also a red flag.

3. Benefits of Hiring a Local Contractor With Compliance Knowledge

Local contractors understand Lahore’s building codes, utility connections, and food safety rules. This cuts down inspection risks and speeds up approvals.

Case Study: One mill project in Lahore finished on time because the contractor had experience and clear planning. Another project faced delays of 6 months because the builder had no mill experience and missed legal approvals.

Future Trends in Mill Construction in Lahore

The way mills are built in Lahore is changing fast. Investors now look beyond basic setups. A modern rice processing plant in Lahore isn’t just about grinding grain it’s about smart technology, lower costs, and meeting global standards.

1. Automation & Smart Machinery

New mills are adding automated machines that sort, grind, and pack with less human effort. This cuts errors and speeds up production.

2. Energy-Efficient Designs (Solar Panels, Recycling Water)

Builders are now focusing on energy savings. For example, using solar panels to power mills or reusing water in cooling systems. These steps lower running costs and support eco-friendly operations.

3. Export-Driven Construction Upgrades

Since Lahore supplies rice and flour to international markets, many mills are upgrading layouts to meet export rules. From dust-free spaces to bulk storage silos, these designs make products fit for global buyers.

Conclusion: Building the Future of Mills in Lahore

Rice and flour mills are more than just factories they’re the backbone of Lahore’s food supply and exports. From smart design to energy savings, mill construction in Lahore is moving toward modern, efficient, and safe setups.

If you’re planning a project, don’t just look at the cost. Think about long-term value, compliance, and the right construction partner. A trusted team makes sure your mill runs smoothly from day one.

At Highland Properties & Construction, we’ve worked on grey structure, turnkey projects, and specialized mill setups across Lahore. We know the local rules, the best suppliers, and how to deliver on time without hidden costs.

Ready to start your grain, rice, or flour mill project in Lahore? Let’s talk. We’ll guide you step by step and build a mill that’s safe, efficient, and ready for the future.

FAQs About Rice and Flour Mill Construction in Lahore

When people think about starting a mill, they usually have a lot of questions. Here are some common rice and flour mill FAQs in Lahore answered in plain words:

Q1: How Long Does it Take to Build a Flour or Rice Mill?

Ans: It depends on the size. A small mill can take 6–8 months, while a bigger one may need 10–14 months from land prep to full setup.

Q2: What’s the Average Cost of a Medium-Sized Flour Mill in Lahore?

Ans: On average, a medium mill may cost between PKR 250–400 million, depending on land price, machinery choice, and finishing quality.

Q3: Do I Need Government Approval to Start a Rice Mill in Lahore?

Ans: Yes, you’ll need permits for land use, building, and environmental safety. Getting approvals early makes the process faster.

Q4: Can I Expand a Small Mill Later into a Large One?

Ans: Yes, many investors start small and add more machines or storage over time. It’s smart to plan the layout with future expansion in mind.

Leave a Reply