How to Make a Timber Frame Panel

Introduction:

How to make a timber frame panel: Creating tone-on-tone frame panels is a great practice. It can bring warmth and personality to any area. By carefully choosing suitable wood and following the installation process, you can create a beautiful space for your home decor. This guide shows you the simple steps of audio panel construction, from material selection to the finishing touch. Whether you’re a seasoned woodworker or a DIY enthusiast, this project offers a creative opportunity to showcase your craft and enhance your Interior design. Let’s dive into the ins and outs of making sound panels and turn your vision into reality.

1. Learn about Timber Frame Construction:

Definition:

Timber Frame Construction is the assembly of structures using beams and columns held together by traditional woodworking techniques or modern fasteners.

Advantages:

Wood frame panels provide strength, durability, and natural insulation properties, making them an excellent option for homes and businesses.

History:

Wood frames have been used for centuries in many cultures around the world, and examples of wood frame construction date back to ancient civilizations.

2. Select Material:

Wooden Beams:

Choose beautiful wood beams to suit your aesthetic preferences and design. Options include Douglas fir, cedar, and oak.

Sheathing Material:

Plywood or Oriented strand board (OSB) is often used as sheathing material to provide additional strength and stability to wood frames.

Insulation:

Choose insulation materials that provide the best thermal performance and moisture resistance, such as fiberglass sheeting, rigid foam board, or spray foam insulation.

Fasteners:

Use corrosion-resistant materials such as stainless steel screws or nails to fasten wood and siding.

Also Read: Brick Masonry Construction in Pakistan

3. Design and Planning:

Building decisions:

Determine the size, configuration, and architectural style of the timber frame according to the building’s design.

Structural integrity:

Calculate the required size and spacing of the beams to ensure adequate support and load capacity.

Energy Efficiency:

Use insulation materials and technologies to increase the building’s energy efficiency and comply with local codes and regulations.

4. Cutting and Preparing the Wood:

Precision Cutting:

Measure and mark the line of the wood against the house plan to ensure each piece is the correct size.

Sawing Technique:

Use a circular saw, miter saw, or hand saw to cut the wood as long as possible; be careful to make straight and square cuts.

Surface Preparation:

Sand the sides or edges of the wood joists to create a smooth surface and prevent breakage.

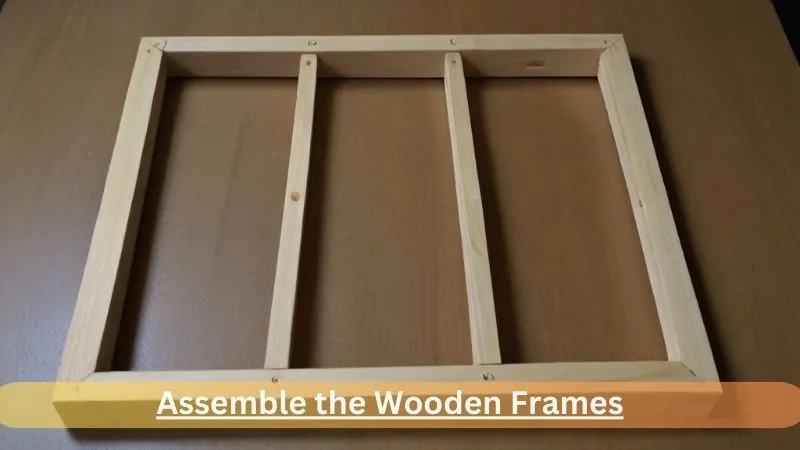

5. Assemble the wooden frames:

Layout:

Place the wooden beams according to the building’s plan to ensure they are in the correct position during assembly.

Joinery:

I am joining wooden beams using traditional wood products such as mortise and tenon or dovetail joints or modern fasteners such as metal brackets or wood screws. [How to make a timber frame panel]

Clamping and Alignment:

Clamps are used to hold the wood frame in place during assembly, ensuring that the joints are tight and working correctly.

6. Additional Insulation:

Improvement:

Improve the insulation of the wooden frame, ensuring a tight fit and good thermal performance.

Vapor Barrier:

Consider installing a vapor barrier on the inside of the insulation to keep out moisture and prevent mold growth.

Fire Safety:

Select appropriate fire-rated insulation that complies with local codes and fire protection.

7. Sheathing Installation:

Sheathing Material:

Cut plywood or OSB to fit the exterior sheathing of the wood posts, making sure they provide adequate support.

Fastening method:

Fasten the cladding panels to the wooden frame using anti-corrosion nails or screws at the intervals recommended by the manufacturer.

Weatherproofing:

Apply weatherproofing or building wrap to the exterior finish for additional protection against moisture and air leakage.

8. Finishing Touch:

Exterior cladding:

Use siding such as siding, brick veneer or stucco to complete the look of wood framing and enhance its beauty.

Interior finishing:

Finish the interior of the wood frame with wood frame panels made of drywall, plaster, or wood, depending on your design and architectural style.

Trims and Details:

Install trims, moldings, and other architectural details to increase visual interest and enhance the overall design of wood frame panels.

9. Installation:

Transportation:

Transport the wooden frames to the construction site and place them carefully according to the construction plan, being careful not to damage them during transportation.

Structural Integration:

Attach the wooden frame to the building’s foundation using appropriate methods and insulation to create a unified and solid structure [How to make a timber frame panel]. Could you also attach it to the walls and roof?

Quality Assurance:

Wood framing panels are carefully inspected during and after installation to ensure consistency, integrity, and compliance with building codes.

Conclusion:

Wood panels require careful planning, execution, and attention to detail. By following the steps outlined in this guide, you can create durable, energy-efficient, and beautiful wood-framed panels that enhance the beauty and functionality of any home [How to make a timber frame panel]. Embrace the timeless appeal and integrity of timber frame architecture and reap the long-term benefits of this home design.

How to make a timber frame panel – FAQs:

Q1. How long does it take to build a wooden house?

Ans: Wooden model: Give yourself two weeks to work on the foundation because it has to be correct. Post-installation only takes 3-4 weeks, depending on the system. Renovation and restoration will take 18-24 weeks. Not all wooden buildings are created equal.

Q2. How is the wooden frame connected?

Ans: The wooden frame is cut so that the ends fit together like a puzzle, and the materials are held together securely with screws. Our nails are separated from straight-grained hardwood logs and shaped by hand with a broach.

Q3. How thick should it be?

Ans: The wall is usually 70mm or 90mm deep, with nails 35mm or 45mm thick, depending on the load and clearance, 450 to 600mm. Skulls are placed between studs to provide lateral support, usually spaced one-half or one-third the height of the wall.

Q4. What size is used for the frame of the house?

Ans: The wall is usually 90 or 70 mm deep with 35 or 45 mm thick studs (depending on load and space), spaced on 450 or 600 mm centers.

Q5. What is the structure of the wooden frame?

Ans: Single-frame construction uses prefabricated (offsite fabricated) exterior and interior stud walls, floor joists, and roof trusses to create a complete structural frame that modifies vertical and horizontal loads in the foundation.

Leave a Reply